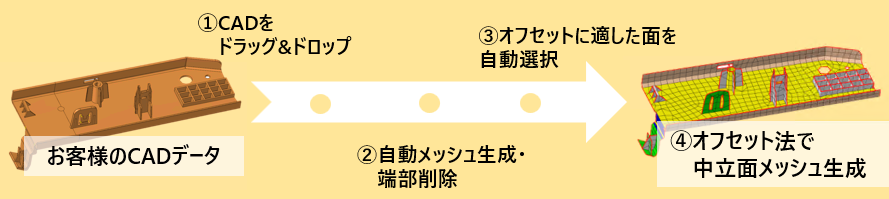

機能と実行フロー

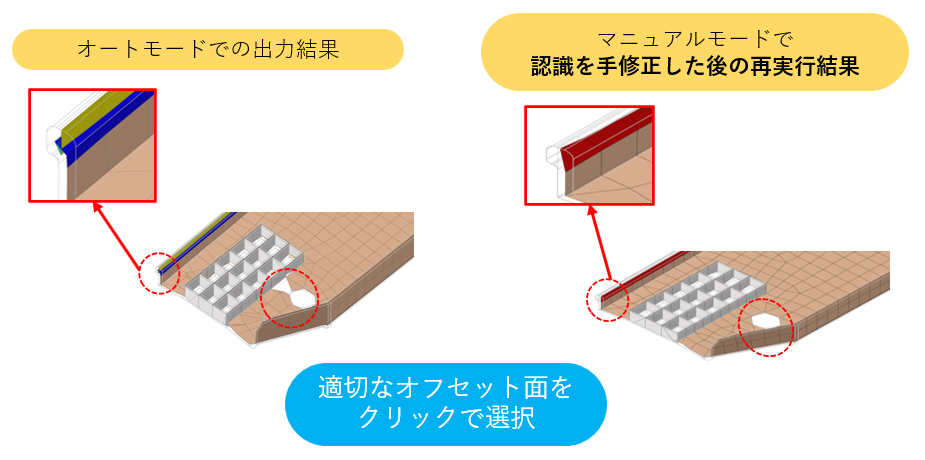

オートモード・マニュアルモードは適宜選択可能

1ライセンスにつき、実行可能ジョブ数は無制限です。

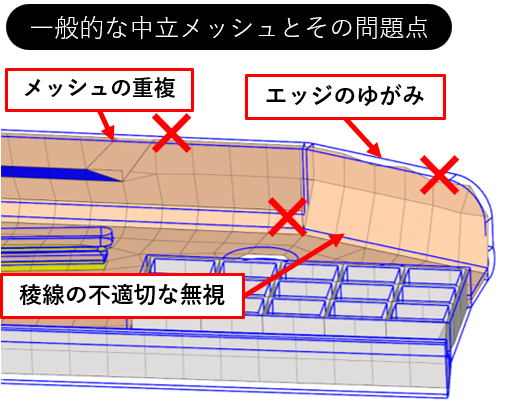

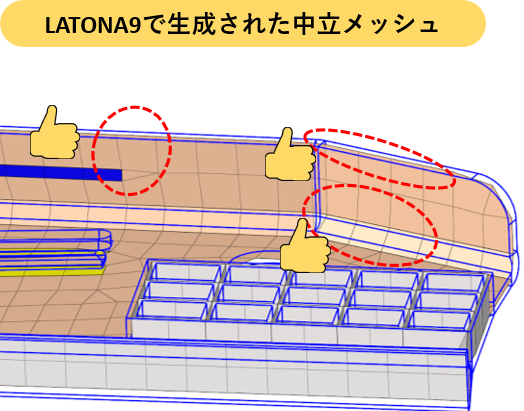

オフセット法による高精度のメッシュ生成

LATONA9は、入力したCAD形状に追随し、実在する形状を中立位置へオフセットして、中立面を生成します。CAD形状に追随することなく中立位置に形状を新規で作り出す他社ソフトと比較して、エラーの少ないことが特徴です。

オートモード・マニュアルモードの自在な切り替え

処理途中の認識を随時、手作業で修正できるマニュアルモードを搭載。処理プロセスのどの段階でも、マニュアルモードに切り替えることが可能です。

メッシュを直接修正するよりも効率的に、正しいメッシュを作成できます。

その他のメッシュソフトにも対応可能ですので、一度お問い合わせくださいませ。

- HyperWorksはAltair Engineering Inc.の登録商標です。