What is FORTUNA_Phoenix?

Aim of the Software

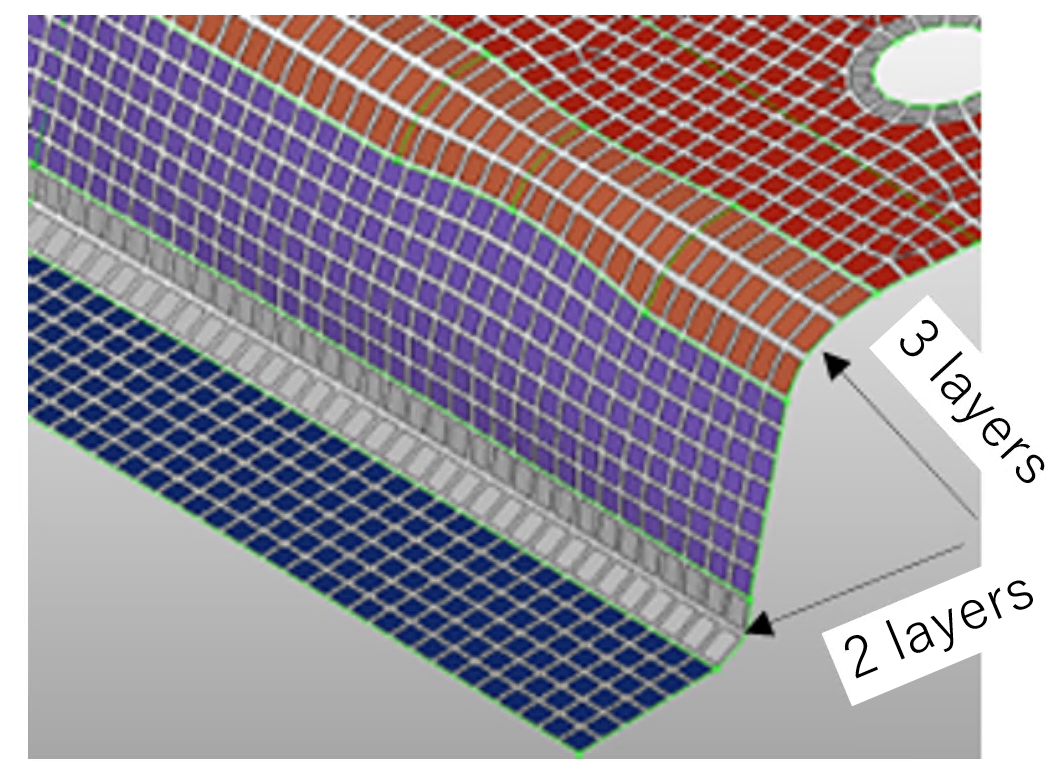

By parameterizing the knowledge of CAE experts and automatically generating mesh that conforms to the parameters for shapes recognized with our unique shape recognition technology, it becomes possible for anyone to automatically create expert-level mesh seamlessly.

Benefits of FORTUNA_Phoenix

- Consistent outcome regardless of the operator

- Automated mesh generation according to meshing rules

- Software robot that runs unattended day and night (Fully automated processing by FORTUNA_Phoenix)

Function Overview

Function List

- Customization and parameter setting for optimizing meshing rules

- Parts replacement, spot welding model

Built-in Functions

Mesh generation process flow

| Execution command | Disassembling | Feature recognition | Mesh generation | Welding | Parts replacement | Report | |

|---|---|---|---|---|---|---|---|

| HyperMesh | Input assembly (Including target parts set) |

Fillet | Time-step keep |

Fillet overlap calculation | Spot location | Remaining errors | |

| Spot welding point calculation | Hole | Fillet edge moving |

Target parts | Spot report | |||

| Disassemble | Bead | Shock wave flow Consideration |

Spot location | ||||

| Flange | Quad mesh priority |

Quad mesh priority | |||||

| Others | General error avoidance | General error avoidance | |||||

| ANSA-based | Spot recognition method | Unique features | Priority order for overlapping fillets and welding | ||||

| Different mesh flow | Bead welding | ||||||

| Associations within the possible range | |||||||

| AI-equipped | Search for CAD issues | Additional feature recognition and mesh pattern | |||||

| Detection of mesh deviating the meshing rules | |||||||

Fillet Mesh Generation Function

- In case the minimum element length cannot be maintained, automatically moving endpoints detected from the surrounding situation to preserve the minimum element length

For element generation with fillet ridge keeping

(1) When fillet width is sufficient

No fillet edge node movement(2) When fillet width is an error

Fillet edge is moved to maintain sufficient widthFor element generation with fillet center keeping

(1) When fillet width is sufficient

(2) When fillet width is an error

No fillet edge node movement

Fillet edge is moved to maintain sufficient width

Merge center nodes to edge nodes

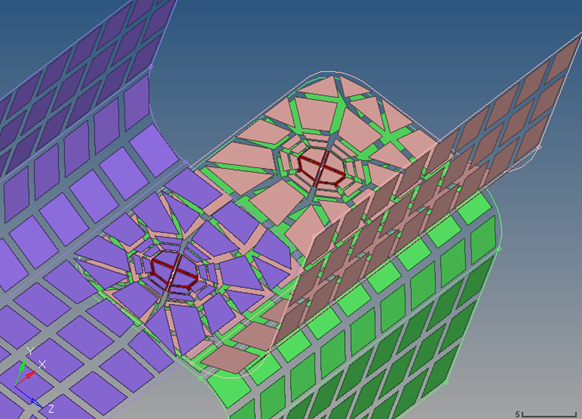

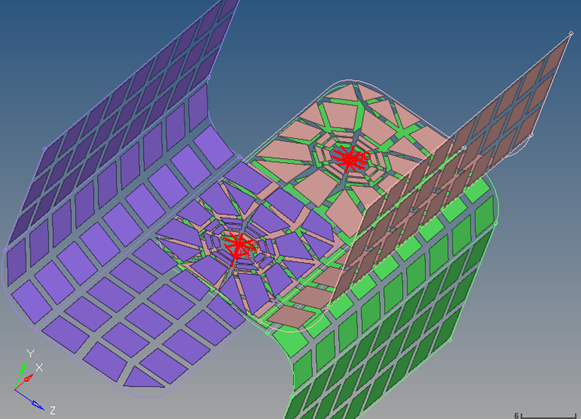

Weld Mesh Generation Function

Standard function: Spot welding

- Mesh control/Assembling

- Spot location/target parts set recognition, Shell mesh conotrol, and Assembling functions are provided as standard functionality

Example of spot weld modeling using HEXA

Example of spot weld modeling using rigids

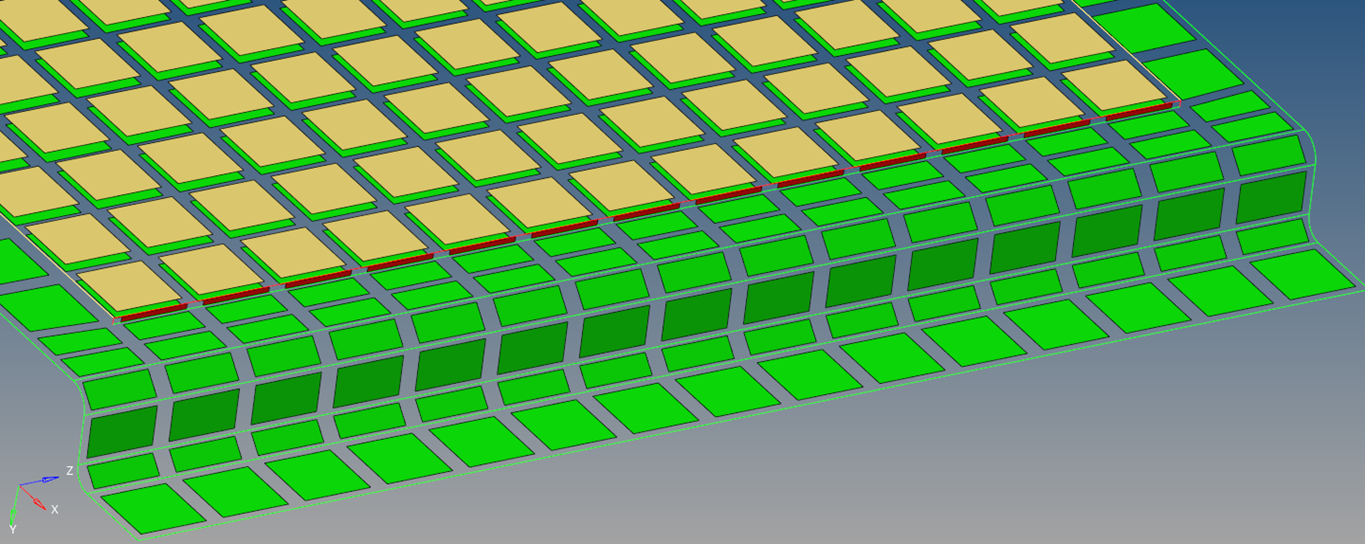

Custumization example: Bead welding

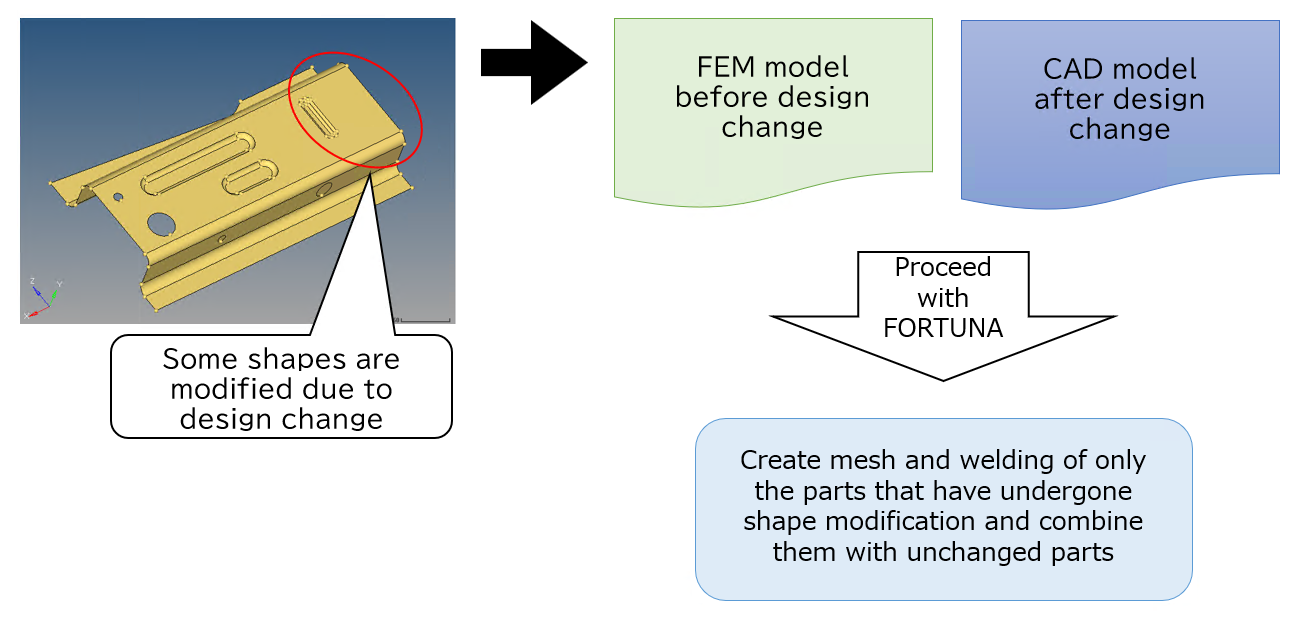

Parts Replacement Modeling Function

- Maintain the mesh for parts other than the changed parts, generate mesh for only the modified parts, and then reassemble

Operation Procedure

GUI of FORTUNA_Phoenix requires only 3 steps and outputs results fully automatially